Isopropanol production from CO2

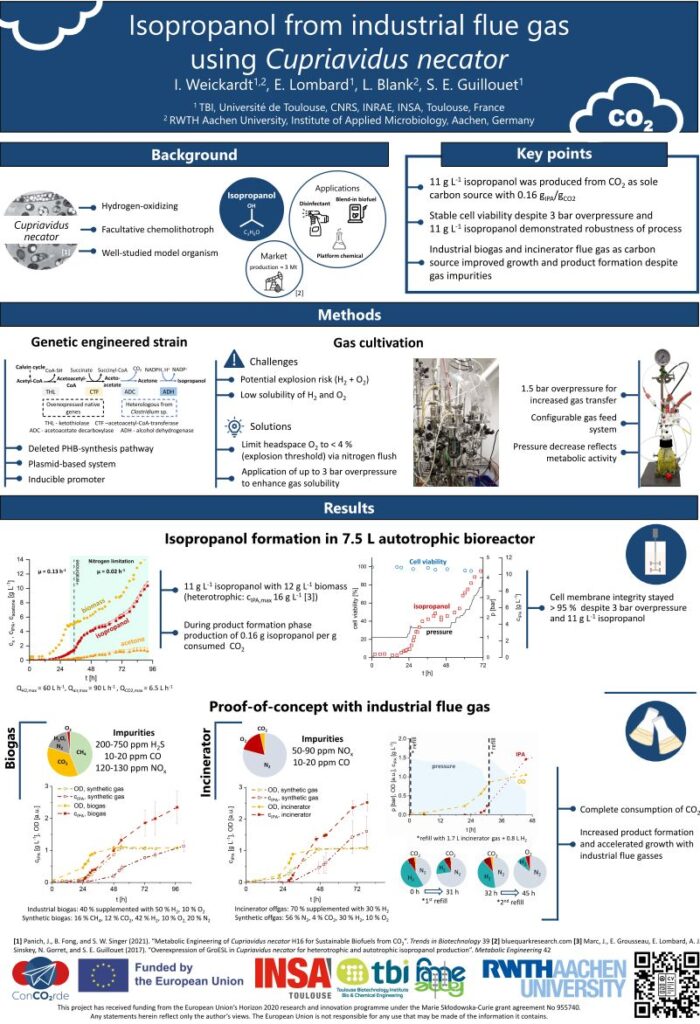

This project focussed on the production of isopropanol by Cupriavidus necator. Isopropanol is the most widely used disinfectant globally and an important building block and blend-in biofuel. Currently, isopropanol is predominantly derived from fossil resources, highlighting the need to develop alternative production methods.

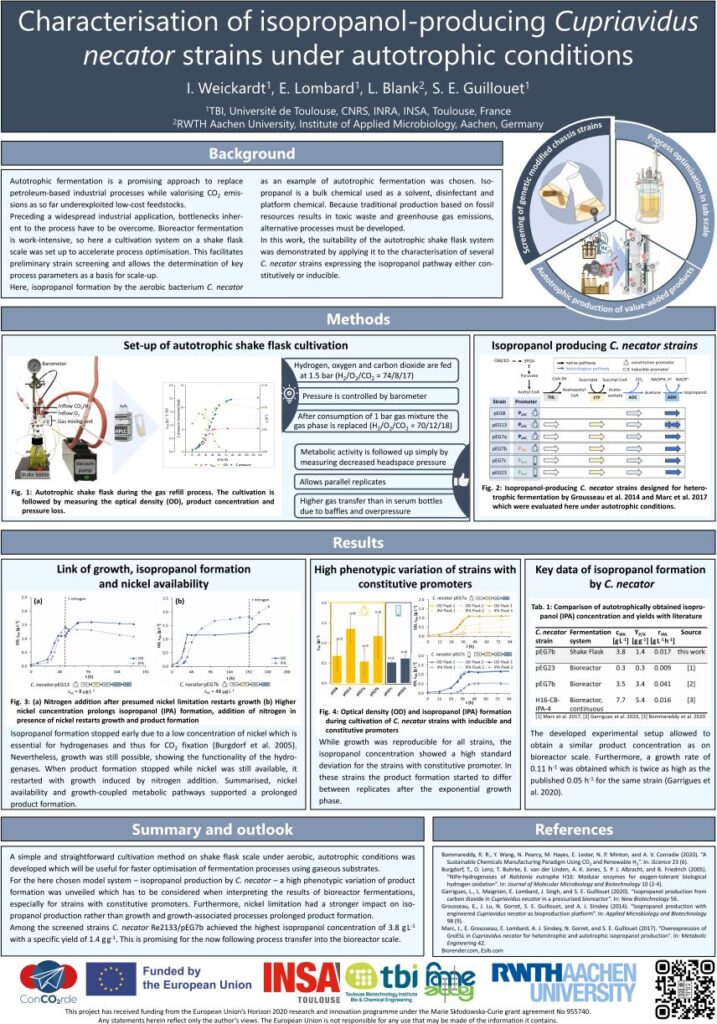

Nature provides innovative solutions, with microorganisms offering remarkable metabolic versatility. The bacterium Cupriavidus necator for example can use carbon dioxide (CO2) as its only carbon source, redirecting the carbon into isopropanol through engineered metabolic pathways. The bacterium derives the energy needed for growth and production by metabolizing hydrogen and oxygen.

The first challenge in this project was to design safe cultivation setups capable of providing sufficient dissolved CO2, H2 and O2. A shake flask system and an efficient bioreactor cultivation strategy were developed. To increase gas transfer to the liquid phase up to 3 bar of overpressure were applied without a negative effect on cell viability. The established cultivation strategy enabled the formation of up to 12 g/L isopropanol within less than four days.

To further validate the process’s industrial applicability, proof-of-concept experiments were conducted using real industrial off-gas streams containing CO2. Flue gas from an industrial incinerator plant as well as biogas were successfully used as carbon sources to produce isopropanol without decreased productivity compared to lab-grade gasses. This underlines the robustness of the bacteria cells, even in the presence of gas impurities.

This work demonstrates efficient biomolecule production under autotrophic conditions and highlights a promising approach to re-integrate CO₂ waste streams into value-added products.

Please fiind all ConCO2rde publications and data (coming soon) at our ConCO2rde community at Zenodo: